The carbon content is too low in 1018 to meet the minimum tensile requirements for A 529 For steel used in A 653, the maximum carbon content permitted is only 015% by mass for certain types and for other types permitted you need microalloying elements added, which is not the case for 1018 You would be wise to stick with what was specified!As can be seen from data above, ASME standard A36 and China standard Q235 materials are named according to yield strength of material, and for SS400 is tensile strength From the analysis of mechanical properties, A36 and SS400 are more equivalent, while Q235 material is less Substitution of A36, SS400 and Q235 steel plate In my area, I can get 1018 cold rolled for about % more than A36 hot rolled 4140 Annealed is 21/2 to 3 times more expensive I don't think I can afford it!

1018 Steel Grade Guide Metal Supermarkets Youtube

1018 steel vs a36

1018 steel vs a36- ASTM A36 steel vs a572 grade 50 While A36 is the less expensive of the two metals, 1018 wins out in most other categories for high quality Less of this material is needed to satisfy given power requirements than is necessary with common carbon steels Carbon Steel and Alloy Steel Marco is a supplier of carbon steel wire cloth and gratings We carry a variety of carbon steel grades including 1018, A36, 1144, 12L14, A366/1008, A513 & 86 There are four types of carbon steel based on the amount of carbon present in the alloy Lower carbon steels are softer and more easily formed, and steels

Cvn Impact Energy Vs Temperature Showing The Dbtt For The A36 Steel Download Scientific Diagram

Both ASTM A36 carbon steel and SAEAISI 1018 steel are iron alloys Their average alloy composition is basically identical There are 31 material properties with values for both materials Properties with values for just one material (1, in this case) are not shown For each property being compared, the top bar is ASTM A36 carbon steel and the bottom bar is SAEAISI 1018 steelASTM A36 steel vs 10 a2grcsteel we'll use numbers for chilly drawn 1018 grade steel 1018 is available in many different sizes and shapes primarily based on the aim and use for the metal including squares, hexagons, rounds and flats Welding A36 to 1018 By jon013 Date 1151 The combination should weld beautifully just as if you were doing A36 to A36 No

Carbon steel, also called plain carbon steel, is a metal alloy, a combination of two elements, iron and carbon, where other elements are present in quantities too small to affect the properties The only other alloying elements allowed in plaincarbon steel are manganese (165% max), silicon (060% max), and copper (060% max) Steel with a Carbon Steel Product Guide Read More » Alloy 1018 is the most commonly available of the coldrolled steels It is generally available in round rod, square bar, and rectangle bar It has a good combination of all of the typical traits of steel strength, some ductility, and comparative ease of machining Chemically, it is very similar to A36 Hot Rolled steel, but the cold rolling1018 Grade 50 = 1018 Grade 50 is an improved high strengthlow alloy material where high strength to weight ratio is needed to produce products which are stronger yet lighter then say an

It has a very good surface finish that is far superior to hot rolled A36 1008 Steel is an economical, general purpose steel grade offering moderate strength and toughness As a standard grade, 1008 steel is used in many common, lowstress applications The term steel refers to iron in which 002 to 17% carbon has been added ASTM A36 steel vs 10;ASTM A36 VS 1018 in Mechanical Properties AISI 1018 steel has a higher tensile strength than ASTM A36 steel Thus ASTM A36 steel is easier to bend than AISI 1018 steel AISI 1018 steel is more expensive because ASTM A36 steel is hot rolled and hot drawn where AISI 1018 steel is cold rolled and cold drawn which is more laber intensive

Difference Between A36 Vs 1018 Steel Surprising Answer

What Is Hot Rolled Pickled And Oiled Hrpo Steel Camden Yards Steel Company

We thought it would be best to provide a comparison for A36 and 1018 steel that outlines those key differences 1018 Steel Like most steel grades, 1018 can be made in cold drawn or hot rolled forms Although we provided information in both the cold drawn and hot rolled forms, 1018 is typically purchased in its cold drawn formBoth ASTM A36 carbon steel and hot rolled SAEAISI 1018 are iron alloys It loses that strength the first time you heat it up to forging temperature because you recrystalize the microstructure Also, when steel scrap is melted, it is carefully sorted and blended to achieve a close match to the desired final product In the back is a typical piece of 1018 hot rolled flat barCall us 0106 9999 858 All Categories Toggle navigation

2

A36 Hot Rolled Steel Plate Ground A36 Plate Dix Metals Inc

Carbon 1018 hot rolled steel from Alro Steel is one of the most commonly available grades in the world Despite its unimpressive mechanical properties, this steel alloy is easily formed, machined, welded, and fabricated It is especially suited to cold forming and bending operations Contact us today to learn moreCandelabra Tree Facts, Masaharu Morimoto Wife, Chakrit Yamnam New Wife, Nee Lambert Age, Kohei Horikoshi Ships, Townie Go 8i, Biting Flies In Ohio, Alejandro Vaughn Rasberry, Lapua Bullets For Hunting, Perforated Foam Backed Headliner Material, Emotional Intelligence Thesis Statement, Ben Jones Pbr, Brett Goldstein Age, L'amérique Pleure Chorégraphie, Mallary House Acnh, WhenInformation on 1008 steel vs 1018 steel Both grades have different chemical and mechanical properties, and it is important to know differences between 1008 and 1018 steel before purchasing either Bellow is a comparison chart with information about the chemical composition and the mechanical properties of both 1008 grade steel and 1018 grade

1

2

A36 ASTM A36 steel is one of the most popular hot rolled steels that Metal Supermarkets sells When it comes to hot rolled steel, Metal Supermarkets carries product with designations from two organizations the American Iron and Steel Institute (AISI) ASTM A36 steel vs 4130 a2grcsteel Unlike most AISI grades such as 1018, 1141, or 4140, American Society for Testing and Materials A36 metal just isn't designated by chemical composition This signifies that while most grades must have added alloys that fit between certain percentages, A36 must meetASTM A36 Steel Vs ASTM 1018 Steel steel plate Leave a Message Get a price EXStock Promotion Center ASTM A36 is the most commonly used mild and hotrolled steel It has excellent welding properties and is suitable for grinding, punching, tapping, drilling and machining processes ASTM 1018 is a low carbon steel with good case hardening qualities

Carbon Content In Carbon Steel Classification Of Steel

2

A36 is a performance standard with a fairly loose allowable range for chemistry The composition standard for 1018 is tighter In practice, I've been told that 1018 is commonly sold as A36 (since it meets the standard), and I have experienced that myself A36 at the minimum allowable strength for that grade will be substantially weaker than 1018 Generally speaking, yes, AISI 1018 should meet the requirements of both A36 and A307, except for heavy plate over ¾" thick However, these ASTM specs will require mechanical testing by a certified lab to be sure the mechanical properties are in accordance with the respective specification Chemistry is only one part of an ASTM specificationRead moreAlloy 1018 is the most commonly available of the coldrolled steels It is generally available in round rod, square bar, and rectangle bar It has a good combination of all of the typical traits of steel strength, some ductility, and comparative ease of machining Chemically, it is very similar to A36 Hot Rolled steel, but the cold rolling process creates a better surface finish and better properties

Grades Of Hot Rolled Steel Metal Supermarkets Steel Aluminum Stainless Hot Rolled Cold Rolled Alloy Carbon Galvanized Brass Bronze Copper

China Sae 10 A36 Aisi 1018 Seamless Carbon Steel Round Pipe Manufacturers Suppliers Factory Mingshang

ASTM A36 is the minimum strength designation 36 KSI This is the cheapest structural grade and what most rebar, chanels, angles, etc are made from The 70 KSI for AISI 1018 is an average strength rating and most of the added strength does come from being cold worked A36 steel is less expensive than 1018 with similar, but less striking finish and machinability characteristics Due to its significant cost advantages, A36 steel is commonly utilized for heavy duty construction and equipment applications Industries that regularly utilize A36 hot rolled steel, include For each property being compared, the top bar is ASTM A36 carbon steel and the bottom bar is hot rolled SAEAISI 1018 ASTM A36 (SS400, S275) Structural Carbon Steel Hot Rolled 1018 Carbon Steel Metric Units US Customary Units

Blackened Steel Finishes For Decorative Metals Wiemann Metalcraft

Correlation Study Between The Surface Magnetic Response And Sinusoidal Axial Tensile Strain On A Butt Weld Connection Performed On Astm A36 Steel Journal Of Materials In Civil Engineering Vol 32 No 8

As two of the most hot selling steel grades on the market, many questions come up between the differences in AISI 1018 steel and ASTM A36 steel As leading AISI 1018 steel and ASTM A36 steel supplier in China, BBN steel takes responsibility and would like to provide a comparrison for AISI 1018 steel and A36 steel ASTM A36 VS 1018 in chemicalA36 Steel vs 1018 Both 1018 and A36 steel are highly useful mild steel grades 1018 steel comes in colddrawn or hotrolled form and contains 018% carbon The main differences between A36 steel vs 1018 steel are provided in Table3 below1018 steel is used over A36 for applications that require machining,because it responds to machining fairly well1018 is most commonly used in high volume screw machine parts including shafts,spindels,pins and rodsA36 is often used as a mass steel product for the industrial and construction industries for making buildings,bridges,railroads,oil rigs and moreA36 is easy to

Astm A36 Pipe Specification Buy 1018 Cold Rolled Steel Round Steel Tubing Sizes Astm A36 Pipe Specification Product On Alibaba Com

Cold Rolled Vs Hot Rolled

Cold Rolled 1018 vs A572 gr 50 By GSCrisi Date 1513 Tim, I've got the ASTM Book before me and A572 is defined as "High strength, low alloy, columbiumvanadium steels of structural quality" On the other hand, SAE 1018 is a low carbon steel with a carbon content of 018 %, with no alloying element whatsoeverA36 This steel is produced using a minimum yield of 36,000 psi It has all the qualities used in structural projects requiring weldments, bolting and riveting fabrications You will find this grade of carbon steel used most often in the construction of buildings, bridges and oil rigsA36 is a standard amongst structural steel in the United States 1018 Carbon Steel 1018 is a low carbon steel known particularly for its exceptional weldability It is often considered the best steel for carburized parts and offers a great balance of durability, toughness and strength

Steel Types And How To Use Them Alec Steele Co

2

Both ASTM A36 carbon steel and SAEAISI 1008 steel are iron alloys Their average alloy composition is basically identical There are 31 material properties with values for both materials Properties with values for just one material (1, in this case) are not shownView A36 vs 1018pdf from MECH ENG ME 362 at University of Waterloo A36 vs 1018 Steel Comparison Capital Steel & Wire 1 of 1 https/wwwcapitalsteelnet/news/blog The following are some common Grades of Hot Rolled Steel A36;

Correlation Study Between The Surface Magnetic Response And Sinusoidal Axial Tensile Strain On A Butt Weld Connection Performed On Astm A36 Steel Journal Of Materials In Civil Engineering Vol 32 No 8

What Is A36 Steel Equivalent

Hi All, I am trying to use carbon steel material that is certified as ASTM A on a Section VIII Div 1 vessel I've checked out thread Is A108 grade 1018 round bar a recognized ma by ASME (SA designation) and found some good info there The material certification I have only lists A108 and 9 in terms of specifications ASTM A36 Carbon Steel vs SAEAISI 1015 Steel Both ASTM A36 carbon steel and SAEAISI 1015 steel are iron alloys Their average alloy composition is basically identical There are 31 material properties with values for both materials Properties with values for just one material (1, in this case) are not shownInitially I was going to use 1018 CRS so that squaring the bar would be easier But I've read that if CRS is machined, it can warp due to internal stresses

China Bright Surface 1008 1018 10 12l14 Ss400 Sc A36 1045 S45c 4140 Cold Drawn Steel Round Bars China Cold Drawn Square Steel

2

The difference between 1018 steel and A36 steel is in the finish, yield strength, and price A36 is favored for structural purposes, while 1018 is more suited for machining and finishing purposes While both 1018 and A36 come in hotrolled or coldrolled forms, hotrolled A36 steel and coldrolled 1018 steel are the most commonA36 Mild Carbon Steel Channel, Angle, Tee, Flats, Plates, Rounds, and Squares ASTM A36 is a structural quality mild carbon steel It's strength, formability, and excellent welding properties make it suitable for a large variety of applications, including welding, fabricating, and bending It should also be noted that A36 has a lower yield strength than C1018 which results in increased bendingIn this Grade Guide video, we take a closer look at this commonly used type of steel

2

1 X 4 1018 Cold Finished Steel Rectangle Bar

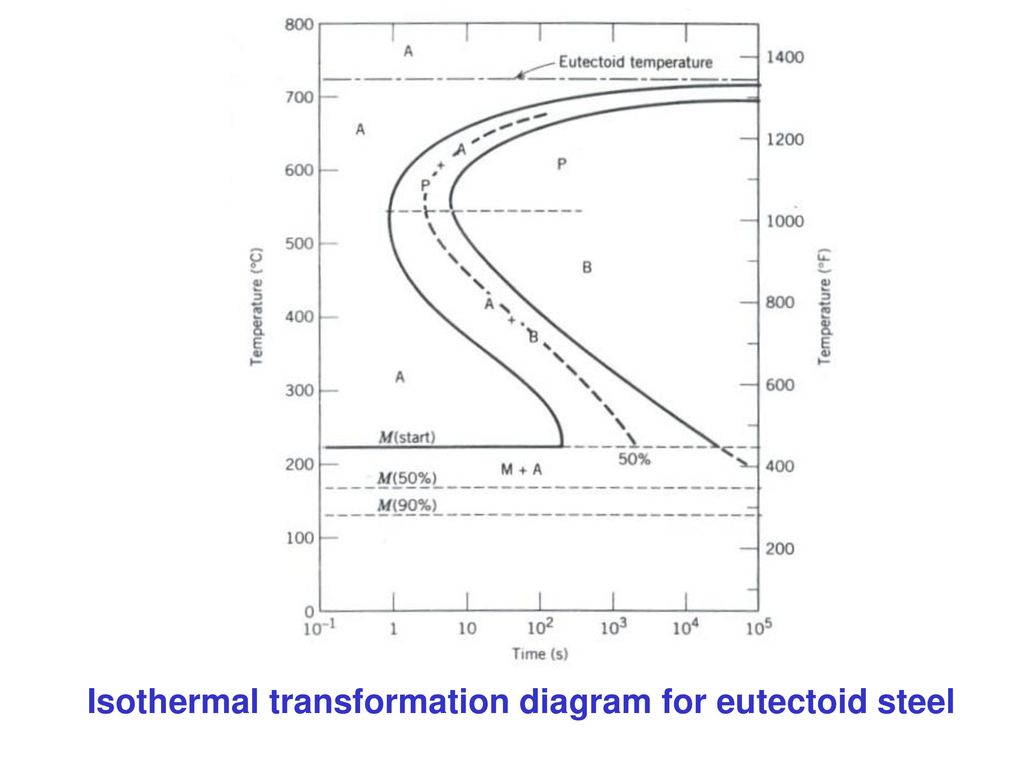

Assembles ASTM A36, A572, 92, A5 and three highperformance steel (HPS) grades into a convenient single standard for bridge designers and fabricators The HPS grades are available in plate form only Grade 50S is available in shapes The other grades are available in plates form and as shapes, though "A36 steel, which is chemically nearly identical to AISI 1018 used in the microstructural comparison, but has a more specialized microstructure Using ftpounds (27 J) for the determination of the ductilebrittle transition temperature, the author 5obtains a transition temperature of 15 o C for the modern A36 steel," One other difference that may be of interest to the blacksmith is that if you buy "1018"cold rolled steel", you can be pretty sure that it has close to a 018% carbon content and few other impurities But the spec for A36 can let the carbon content go as high as 029% and it can contain many more impurities More carbon makes it harder

A 36 Carbon Steel Carbon Hot Rolled Steel A 36 Steel Channel Angle Tee A 36 Structural Steel

What Is A36 Steel Equivalent

A36 vs 1018 Steel Comparison a mild low carbon steel with good ductility, toughness A36,SS400,C,S235JR,S355JR/JO/J2,A572,A573,Q4,Q460 steel

What Is Forged Steel

Blackened Steel Finishes For Decorative Metals Wiemann Metalcraft

0 750 X 0 750 A36 Hot Rolled Square Bar

Astm A36 Mildlow Carbon Steel Steel Strength Of Materials

Amazon Com 1018 Carbon Steel Round Rod Unpolished Mill Finish Cold Finished Temper Astm A108 0 125 Diameter 12 Length Industrial Scientific

Railroad Spikes Are Hc Spikes High Carbon The Barefoot Forge

.jpg)

Steel Rolled Bar For Mexico Quality Us Milled Rolled Bar

2

Burn Outs Tool Steel Service Inc

China Cold Drawn 1018 Ss440 A36 Sc S45c Steel Round Bar Bright Steel Bar China Cold Drawn Steel Steel Alloys

9imxvj5qhgxcem

1018 Steel Grade Guide Metal Supermarkets Youtube

Amazon Com Arsport A36 Hot Rolled Steel Round Rod 1 50 Od X 6 Inches Lathe Projects Automotive

Carbon Steel Types Differences Between Carbon Steel And Stainless Steel

A36 Vs 1018 Rolling Metalworking Steel

A36 Properties Pdf Steel Strength Of Materials

Blackened Steel Finishes For Decorative Metals Wiemann Metalcraft

2

2

Amazon Com A36 Steel Sheet Annealed Precision Ground Astm A36 1 Thickness 1 Width 24 Length Industrial Scientific

Heat Treating 1018 Steel Steel Choices

1 X 2 5 A36 Hot Rolled Rectangle Bar

Steel Bar Precision Grinding Inc

1 2 X2 Cf 1018 Rectangle X 60 Length

2

2

Hot Rolled Steel Grades

2

2

Correlation Study Between The Surface Magnetic Response And Sinusoidal Axial Tensile Strain On A Butt Weld Connection Performed On Astm A36 Steel Journal Of Materials In Civil Engineering Vol 32 No 8

Blackened Steel Finishes For Decorative Metals Wiemann Metalcraft

Are You Properly Specifying Materials Pages 1 6 Flip Pdf Download Fliphtml5

Correlation Study Between The Surface Magnetic Response And Sinusoidal Axial Tensile Strain On A Butt Weld Connection Performed On Astm A36 Steel Journal Of Materials In Civil Engineering Vol 32 No 8

2

Cvn Impact Energy Vs Temperature Showing The Dbtt For The A36 Steel Download Scientific Diagram

1

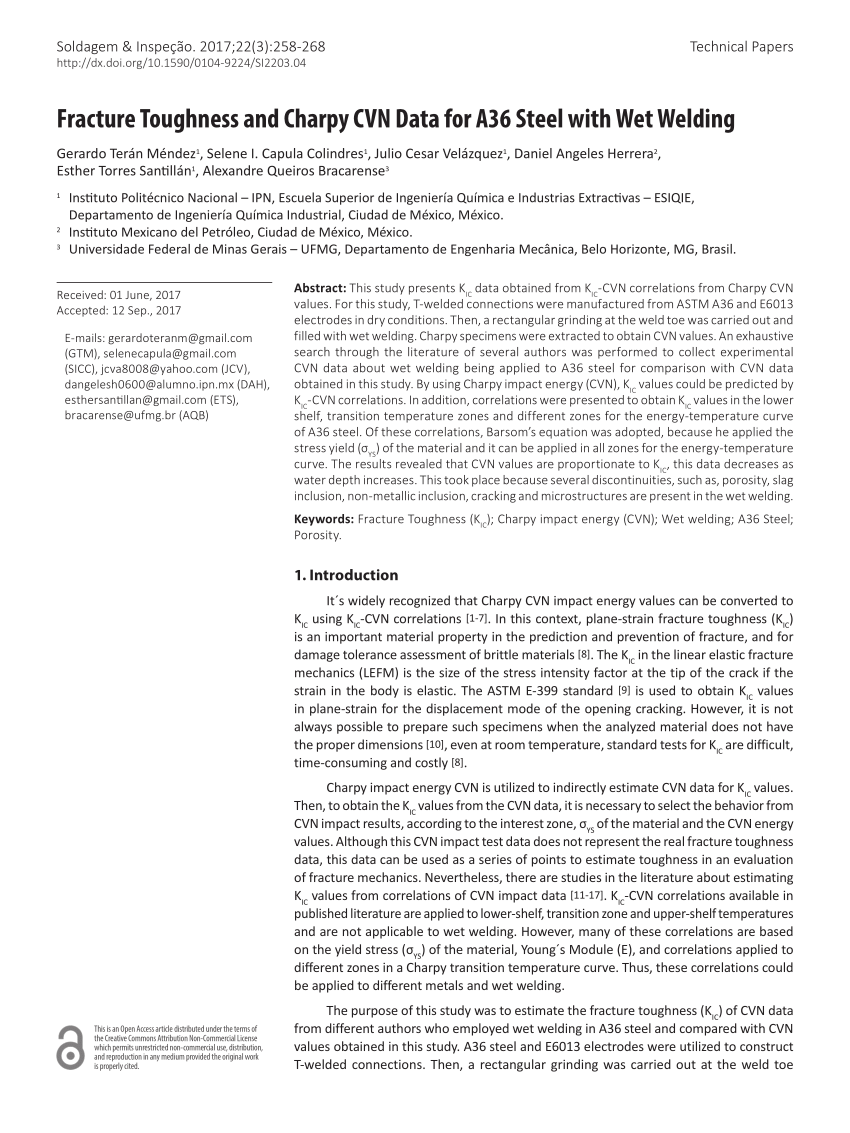

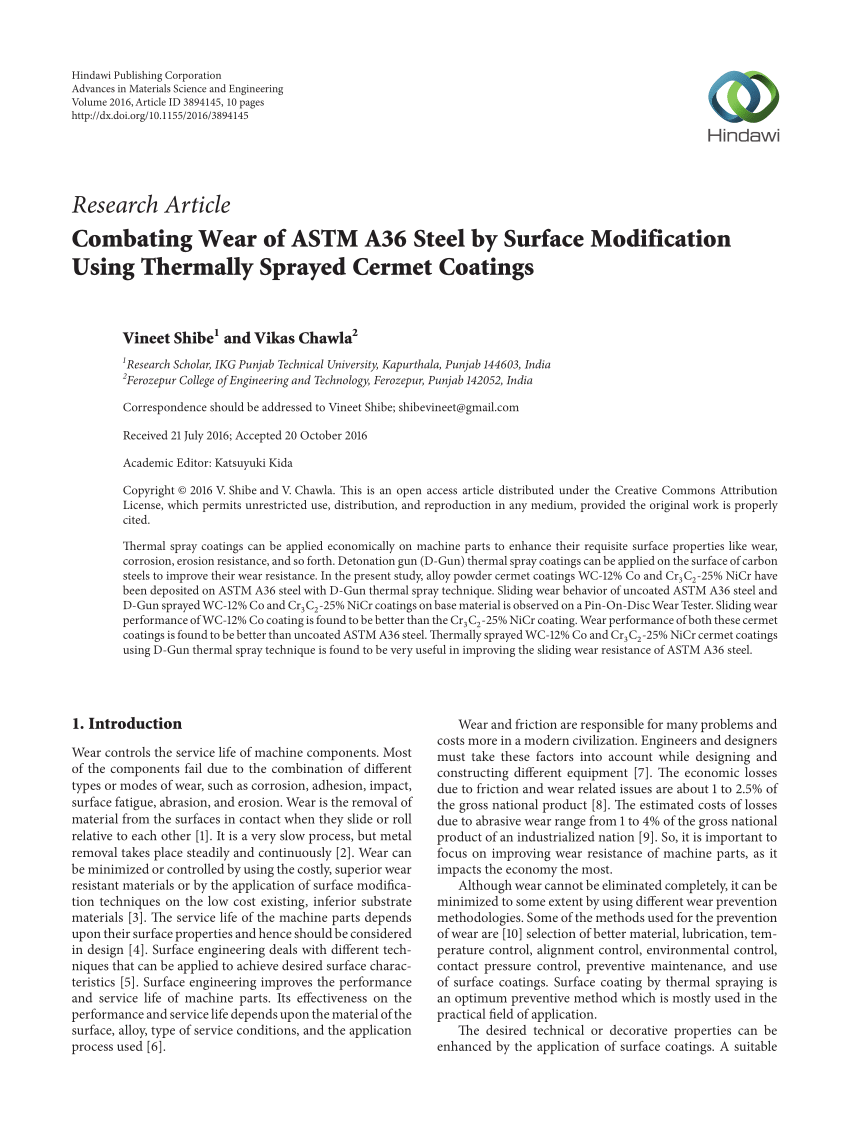

Pdf Combating Wear Of Astm A36 Steel By Surface Modification Using Thermally Sprayed Cermet Coatings

Plant Engineering Mild Steel Welding Find The Right Filler

2

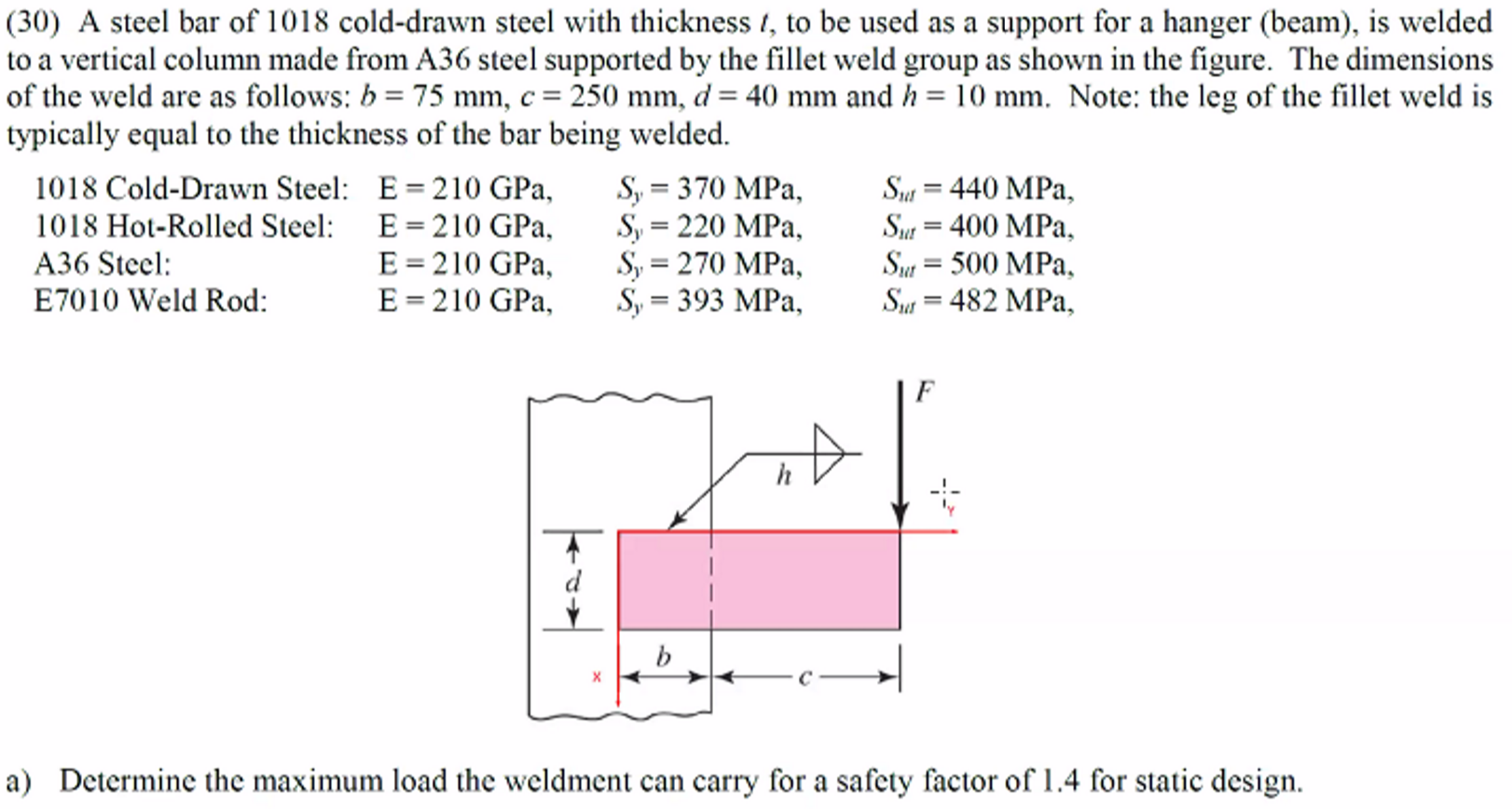

30 A Steel Bar Of 1018 Cold Drawn Steel With Chegg Com

Welding Metallurgy Welding Of Steels Ppt Download

Carbon Steel Wire Cloth Grating Expanded Perforated Sheet Marco Specialty Steel

Practical Machinist Largest Manufacturing Technology Forum On The Web

A1011 Vs A36

2

grc Vs A36 Comparison Pdf Structural Steel Steel

1

Y 400 Mm 350 Mm 25 300 Mm 50 Mm Dia Gear A Chegg Com

2

What Is The Difference Between Sa36 And A36 Metals

A Guide To Carbon Steel Grades Plus A Chart

2

Evaluation Of The Low Cycle Fatigue Life In Seven Steel Bar Types Journal Of Materials In Civil Engineering Vol 28 No 5

1018 Steel Grade Guide Metal Supermarkets Youtube

Amazon Com Carbon Steel 1018 Rectangular Bar Cold Finished Astm A108 1 8 Thick 3 8 Width 36 Length Industrial Scientific

Pin On St12 St37 A36 A572 Ss400 Steel Plate

Pdf Modeling Of The Growth Kinetics Of Boride Layers In Powder Pack Borided Astm A36 Steel Based On Two Different Approaches

Cnc Steel Material Cnc Machining Steel Fictiv

A36 Hot Rolled Steel Plate Ground A36 Plate Dix Metals Inc

2

Cvn Impact Energy Vs Temperature Showing The Dbtt For The A36 Steel Download Scientific Diagram

Correlation Study Between The Surface Magnetic Response And Sinusoidal Axial Tensile Strain On A Butt Weld Connection Performed On Astm A36 Steel Journal Of Materials In Civil Engineering Vol 32 No 8

2

Order 1 Mild Steel Plate A36 Blanchard Ground Online Thickness 1

Grade Guide A36 Steel Metal Supermarkets Steel Aluminum Stainless Hot Rolled Cold Rolled Alloy Carbon Galvanized Brass Bronze Copper

12l14 Steel Bar Supplier 12l14 Properties Eaton Steel Bar Company

Railroad Spikes Are Hc Spikes High Carbon The Barefoot Forge

What Is Forged Steel

Need Help Steel Feeds And Speeds

China Cold Drawn 1018 1045 4140 Ss440 A36 Sc S45c Steel Steel Bar China Suppliers Photos Pictures Made In China Com

Carbon Steel Astm A36 Fasteners Carbon Steel Astm A36 Nuts Bolts Screws Washers Suppliers

2

Amazon Com A36 Steel Angle Unpolished Mill Finish Astm A36 Equal Leg Length Rounded Corners 1 2 Leg Lengths 0 125 Wall Thickness 12 Length Industrial Scientific

China Ss440 A36 Sc 10 S45c 1018 1045 4140 12l14 1215 Cold Drawn Polished Steel Round Square Hexagonal Bars China S45c Cold Drawn Steel Bar 1045 Cold Drawn Steel Bar

Scielo Brasil Friction Stir Welding Of Shipbuilding Steel With Primer Friction Stir Welding Of Shipbuilding Steel With Primer

In Stock Wholesale Pickled Oiled A 36 Steel Angle

1

2

Aisi 1018 Aisi 10 Aisi 1080 Carbon Steel Plate Buy Aisi 1018 Steel Plate Aisi 1080 Steel Plate Aisi 10 Carbon Steel Plate Price Product On Alibaba Com

China Sae 1008 1018 10 A36 1045 4140 Cold Drawn Bright Surface Steel Bars China Sae 1008 Cold Drawn Steel Bar Sae 1018 Cold Finished Steel Bar

0 件のコメント:

コメントを投稿